The master plan takes into account the structure of flows and orders, as well as the planned growth thereof. It provides process and business security for the organization. It includes a choice of technologies, also in terms of flexibility and availability. It may be implemented with a new warehouse in mind, or with a view to reorganise an existing one.

Service provision process

01 ANALYSES AND FORECASTS

Analysis of orders, rotation, and stock assortment; including modelling/forecasting

02 TECHNOLOGY SELECTION PROCESS

Vision for the warehouse and technical dialogue

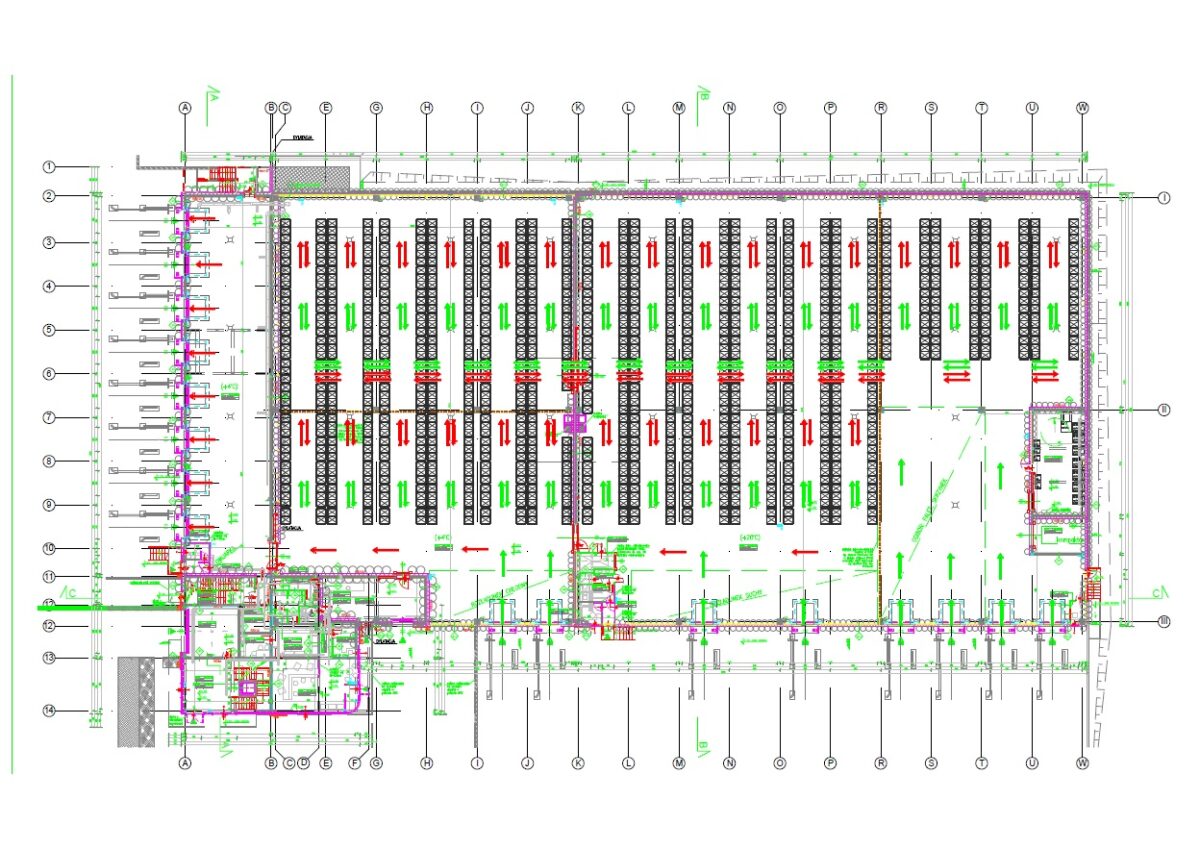

03 LAYOUT

Visual verification of the concept – zones, technologies, communication, others

04 BUDGET AND THE ROADMAP

Calculations of investment costs and operating costs as well as constituent ROI for particular processes

The results

- The most economical and process-friendly solution

- Optimal use of floor space and volume and other available resources

- Taking into account the fire protection requirements in the design

- Taking into account the limitations of individual technologies

- Decisions independent of equipment suppliers

- Ensuring future flexibility, phasing investment projects

- Security of decisions and investment outlays

Case study

Warehouse vision: 3 scenarios with storage system proposals and Business Case: CAPEX, OPEX, ROI.

In the eye of an expert

Cost effectiveness and ensuring flexibility are the most common requirements of companies where logistics and the warehouse that is responsible for it constitute a significant competitive advantage.

Development of the master plan is a process of searching for an optimal solution. It comprises flow analysis tools, proven methods of solving complex problems, as well as the accumulated experience of people who design several warehouses each year across various industries.

Łukasz Musialski

Senior Consultant

Contact regarding the offer

Bartosz Jacyna

Partner, Business Development